BCM environmentally friendly conductive screen-printable inks

BCM have recently published a journal paper on Environmentally Friendly Conductive Screen-Printable Inks Based on N-Doped Graphene and Polyvinylpyrrolidone

https://onlinelibrary.wiley.com/doi/full/10.1002/adem.202101258

Authors:

Miguel Franco, Azadeh Motealleh, Carlos M. Costa, Loic Hilliou, Nikola Perinka, Clarisse Ribeiro, Júlio César Viana, Pedro Costa, Senentxu Lanceros-Mendez

Abstract

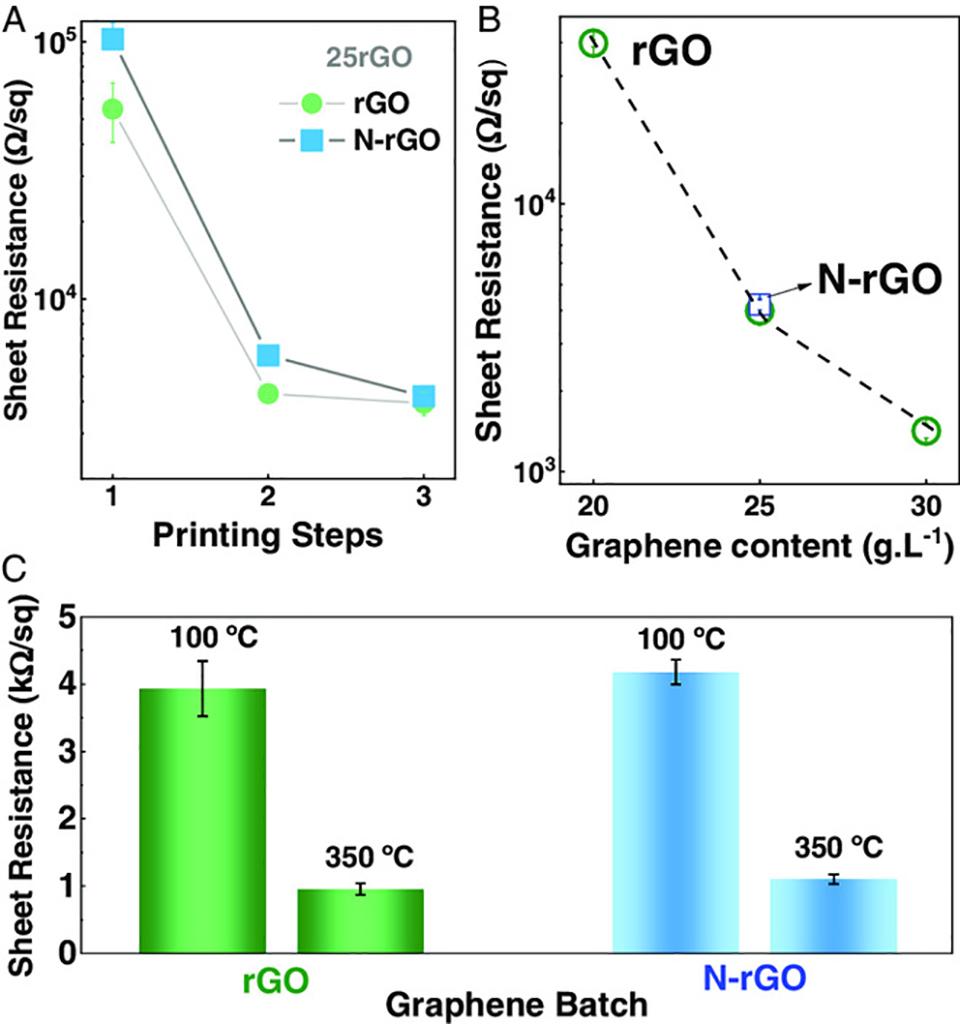

The development of polymer-based conductive inks has gained increasing interest in the areas of printed and molded electronics. Graphene-based materials are explored in this scope, reduced graphene oxide (rGO) being among the most used conductive filler components of the inks. Herein, rGO is doped with nitrogen to obtain N-rGO; the replacement of oxygen atoms by nitrogen ones increases the electrical conductivity of graphene. Polymer-based conductive inks reinforced with graphene are developed based on polyvinylpyrrolidone (PVP) as polymer binder and dihydrolevoglucosenone (Cyrene) as solvent, leading thus to environmentally friendly conductive inks. Screen-printable inks are optimized in terms of viscosity and adhesion properties, leading to printed films with sheet resistance close to Rs = 1 kΩ sq−1, the graphene:PVP inks being also biocompatible and nontoxic.

Figure 1

Experimental procedure for the preparation of the rGO-based inks. The corresponding amount of Cyrene and PVP was placed into a glass for 1 h at 200 rpm (first step); graphene was then added and further stirred at 2000 rpm for 1 h (second step). After preparation, the inks were printed by screen printing (step 3) with three printing passes followed by a curing step at 110 °C for 15 min.