WEARPLEX Beta Workshop Webinar - Video and Presentations

This is a recording of the webinar workshop for the EU funded H2020 research project, WEARPLEX. Watch the full video here: Link

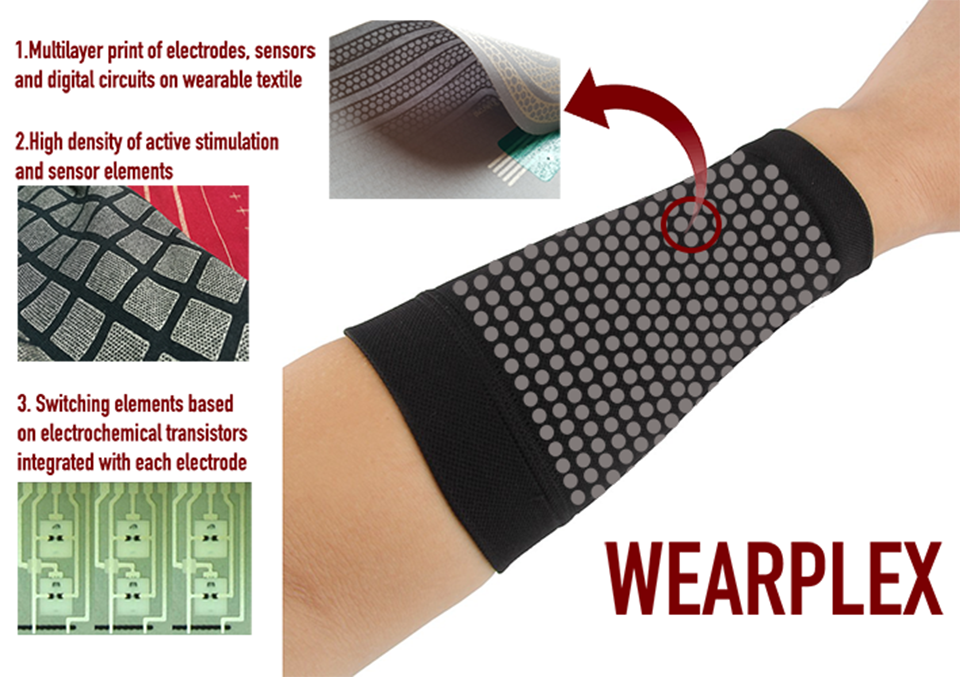

WEARPLEX is developing printed wearable electrodes for biomedical applications with both recording of physiological electrical signals and electrical stimulation of muscles. This is achieved via novel printed organic transistors and electrode patterns printed directly on to wearable textiles.

There was a general introduction to the project and the consortium and then a series of quick fire presentations on the key technologies in the project. After this there were live demonstrations of the work so far. During the webinar there were opportunites for questions and discussion on how this technology could be used in your applications and an opportunity to complete a Padlet and questionaire although both are those are now closed. If you have any feedback then please contact the coordinators at the Univeristy of Southampton (Russel Torah - rnt@ecs.soton.ac.uk or Steve Beeby - spb@ecs.soton.ac.uk) or any of the technology partners directly.

The demonstrator videos can be seen here:

|

Title |

Presenter |

YouTube link |

|

Demonstration of WEARPLEX EMG recording system Live/Video |

Luis Pelaez Murciego |

|

|

Demonstration of WEARPLEX Stimulation testbed Live/Video |

Milos Kostic |

|

|

Demonstration of WEARPLEX stimulation/recording electronics |

Pierre Barralon |

A short summary of each of the technology talks and links to the powerpoint slides/videos are shown below:

|

Title |

Partner |

Presenter |

|

Introduction to EU-H2020 project WEARPLEX: Wearable multiplexed biomedical electrodes |

UoS

|

Russel Torah |

|

This presentation introduces the key concepts behind the WEARPLEX project, the consortium members and their development roles within the project. It gave an introduction to the state of the art technologies involved and how the project intends to go beyond this. Details were also provided of how to get involved in the project and our social media and website links. |

||

|

Link: Here |

||

|

|

||

|

EMG recording applications |

AAU |

Strahinja Dosen |

|

The presentation introduced the application of WEARPLEX technology to the recording of multichannel electromyography (EMG). First, a concept of multichannel EMG was explained and how multichannel EMG can be combined with machine learning (pattern classification) to estimate user movement intention. State of the art systems for EMG-based control using gesture recognition have been briefly presented, and the advantage of the WEARPLEX approach has been explained (textile-based dry multichannel solution). Finally, preliminary results of switching of the state of the EMG channel using OECT components have been illustrated. |

||

|

Link: Here |

||

|

|

||

|

Electronic inks for biomonitoring applications |

BCM |

Nikola Perinka |

|

This presentation described the developments at BCMaterials in terms of the ink development specifically for biomonitoring applications. Some of these developments were also done in collaboration with project partner Abalonyx who specialize in reduced Graphene Oxide synthesis for new conductive inks. Advanced biomonitoring applications require development of new inks with tailored functional properties, such as high electronic/ionic conductivity, biocompatibility and flexibility/stretchability. Within WEARPLEX, BCMaterials has developed different kinds of inks, from dielectric to semiconducting inks and magnetic inks. Some of these inks have also been developed in accordance with specific project-related requirements, such as biocompatibility for applications in contact with human skin, as well as the green approach to comply with sustainability aspects of the future fabrication processes. The most directly relevant inks for the WEARPLEX project were described in this presentation. |

||

|

Link: Here |

||

|

|

||

|

E-textile integration |

UoS |

Abiodun Komolafe |

|

This presentation focused on the techniques employed at the University of Southampton to integrate electronic functionality into textiles. The use of screen printing to functionalize the textile with conductive inks was discussed giving an overview of the technology and example e-textile prototype devices that had been fabricated with this technology. Emphasis was placed on the fabrication of wearable electrodes on the primer/interface layer technology developed at UoS to smooth the surface of the textile. Published results on the reduction of the thickness of this primer layer based on the fabric material and properties to improve the wearability of WEARPLEX electrodes were also highlighted. Lastly, the integration of flexible filament circuits into textiles using the weaving process was also described showing example devices fabricated at the UoS. This process is to be combined with the screen-printing process to seamlessly embed the control electronics for the WEARPLEX electrodes into textiles. |

||

|

Link: Here |

||

|

|

||

|

Soft Skin-Electrode Interface |

IDUN |

Katja Junker |

|

The presentation gave a short overview of IDUN Technologies and the types of electrodes that were developed/are still in development. The soft, conductive material, the DRYODE™ Ink that was developed by IDT after the release of their first product and that is also used as soft skin-electrode interface material in the WEARPLEX project, was presented. Based on the same material system, a stimulation variant of the ink was especially developed for WEARPLEX FES applications. A short overview of the progress achieved in the BETA stage, compared to the ALPHA prototype was given. The presentation was concluded with an outlook for further developments.

|

||

|

Link: Here |

||

|

|

||

|

FES applications |

TECSR |

Matija Strbac |

|

The presentation showcased the application area of electrical stimulation and how the multi-pad electrode concept can significantly improve the impact of this technologies in different domains. Examples of biomedical electrodes use for electrical stimulation in neurorehabilitation, posttraumatic rehabilitation and human-machine interfacing. The added value that the WAERPLEX concept can bring in this context was explained and illustrated on the examples of smart multiplexed electrodes for human-machine interaction and pain therapy. Finally, the main results of the beta demonstrator technical validation were presented, and the demonstrator was introduced. This provided a good basis for the later demo session where the prototypes were shown in action. |

||

|

Link: Here |

||

|

|

||

|

Screen Printed OECT-based Logic Circuits |

RISE |

Peter Andersson-Ersman |

|

The presentation introduced organic electrochemical transistors (OECT) and OECT-based logic circuits manufactured by screen printing. The advantages of the technology are: low-voltage operation, high current throughput and scalable production at high manufacturing yield, thereby allowing for implementation in the targeted WEARPLEX demonstrators. The printed logic circuits enable addressability in the multi-pad electrodes, and the high current throughput allow for transfer of biphasic pulses in the stimulation application. The printed circuits may also be used as digital switches to control the transfer of EMG signals in the recording application. The major challenges of the technology are operational lifetime, inherent humidity dependence and process transfer from plastic- to textile-based substrates, and strategies to mitigate these challenges were briefly discussed. |

||

|

Link: Here |

||

|

|

||

|

Scaleup printing |

TUC |

Maxim Polomoshnov |

|

The presentation introduces the scaleup workflow including the main steps of the printing upscaling and their aims: lab-scale production, lab-to-fab transfer, pilot and industrial manufacturing lines. The production processes performed by TUC were demonstrated based on the achieved results within WEARPLEX. Upscaling processes outside the project were shown auxiliary for the steps not yet performed within WEARPLEX. S2S flatbed screen printing and manual layout positioning is applied for the initial lab-scale production, R2R rotary screen-printing and hybrid machines and increasing process automation are envisaged for the transfer and industrialization upscaling phases. Printing on paper and textile substrate using various inks were demonstrated, possible production issues were pointed out. Finally, the anticipated pilot and industrial manufacturing lines were briefly discussed. |

||

|

Video: Watch |

||

|

|

||

|

Electrode Manufacturing |

SCT |

Jenni Isotalo |

|

In this presentation Screentec presented manufacturing of the printed electrodes. For over 10 years Screentec has been applying its knowledge and experience in the field of printed electronics to manufacture custom disposable medical electrodes. This presentation includes the processes that Screentec has in-house. Screentec has started to develop a camera system for controlling and verifying the quality of the printed sheet. This camera system will know if the printed layers are in the right position on the film, and if they have the right distance from each other. Screentec will develop the camera system that it can be used also for statistical analysis. |

||

|

Link: Here Video: Watch |

||

|

|

||